Top 5 Must-Have Jigs for Precision in Woodworking Projects.

Woodworking is not just a craft, it’s an art form. And like any good artist, a woodworker needs precision and the best tools to bring their visions to life. Enter the woodworking jig – a must-have in your toolkit, helping you achieve precise cuts, angles, and finishes. But with so many types out there, which ones should you focus on? Let’s dive into the top 5 precision woodworking jig ideas that will elevate your crafting game.

👉CLICK HERE TO GET STARTED

Watch to learn more about the numerous applications and benefits of these woodworking jigs, and prepare to take your craft to the next level!

Key Insights

When diving into the world of precision woodworking, the tools and techniques you choose can dramatically impact the quality and efficiency of your work. Jigs, in particular, are pivotal in transforming a good woodworking project into a great one. These are not just tools; they are your partners in the crafting journey. Let’s explore some key insights about how jigs can enhance your woodworking endeavors:

Transforming Challenges into Opportunities

Jigs have a unique way of turning intricate woodworking challenges into manageable, repeatable processes. They provide the precision and consistency required to execute complex designs with ease. This means less time fretting over measurements and cuts, and more time bringing your creative visions to life.

Enhancing Craftsmanship and Quality

The use of jigs directly correlates with the level of craftsmanship in your finished projects. They help ensure cuts are straight, angles are accurate, and measurements are precise. This accuracy is crucial when crafting joints, fitting parts, or creating decorative elements, directly impacting the durability and aesthetic appeal of your work.

Increasing Safety and Confidence

Woodworking can be daunting, especially when dealing with power tools and complex machinery. Jigs offer a significant safety benefit by securing materials in place and guiding tools with precision. This reduces the risk of accidents and increases your confidence, allowing you to focus on the craftsmanship rather than worrying about your fingers.

Saving Time and Materials

Jigs are not just about precision; they’re also about efficiency. By standardizing the more tedious or complex parts of your workflow, jigs can save you an immense amount of time and reduce material waste. This efficiency is especially beneficial in professional settings where time is money and material costs can add up quickly.

Enabling Repetition and Scalability

Whether you’re producing multiple pieces of the same design or scaling up your operations, jigs are an invaluable asset. They allow you to replicate the same high-quality cuts, holes, or joints effortlessly. This is essential for maintaining consistency across multiple items, whether you’re crafting bespoke furniture or custom cabinetry.

Facilitating Learning and Experimentation

For beginners and seasoned professionals alike, jigs serve as both teachers and test beds. They allow less experienced woodworkers to achieve more precise results and encourage more experienced crafters to experiment with new techniques and designs. This dual role fosters skill development and innovation in your woodworking practice.

Cultivating a Professional Workflow

Incorporating jigs into your workflow not only enhances the quality of your work but also projects a level of professionalism and dedication to your craft. This is crucial for those looking to sell their work or build a reputation in the competitive field of woodworking.

Adapting to New Technologies

As woodworking technologies evolve, so do the jigs. Modern jigs are designed to work seamlessly with the latest tools and machinery, from CNC routers to advanced table saws. Staying updated with the latest jigs can provide a competitive edge by allowing you to take advantage of new techniques and materials.

By understanding these key insights, woodworkers can better appreciate the pivotal role that jigs play in enhancing their craft. Whether you’re a hobbyist looking to improve your skills or a professional aiming to streamline your operations, the strategic use of woodworking jigs is an undeniable boon.

Fixtures and Guides

In the realm of precision woodworking, fixtures and guides stand as the cornerstone of accuracy and efficiency. These tools are designed to ensure repeatability and precision in every project, making them indispensable for both novices and seasoned craftsmen. Let’s explore how fixtures and guides can revolutionize your woodworking process.

Essential Role of Fixtures

Fixtures are primarily used to securely hold your workpiece in place during operations. This is crucial for tasks requiring high precision, such as cutting, drilling, or milling. By immobilizing the material, fixtures eliminate the risk of movement that could lead to inaccuracies or even dangerous kickbacks. They come in various forms, including clamps, vices, and custom holders, each tailored to specific tasks and tools.

Benefits of Using Fixtures

- Consistency: Fixtures ensure that every piece is handled identically, which is especially important when producing multiple items of the same design.

- Efficiency: With the workpiece firmly secured, operations can be completed more quickly and with less effort, as there’s no need to reposition the material continually.

- Safety: Reducing the need for manual holding decreases the chance of accidents, keeping your fingers well away from blades and bits.

The Guide to Guides

Guides serve as your roadmap for making precise cuts or holes. They direct the tools along predetermined paths, ensuring that each pass is executed with exactitude. Guides can be as simple as a straight edge clamped to a piece of wood or as intricate as a laser guide on power tools. They are particularly crucial in achieving straight cuts with saws or perfectly aligned holes with drills.

Why Guides are Game-Changers

- Precision: Guides remove the guesswork from cutting and drilling, allowing you to follow exact measurements and lines.

- Versatility: They can be adjusted to suit various sizes and shapes of materials, making them suitable for a wide range of projects.

- Ease of Use: Once set up, guides make the cutting process smoother and faster, enabling even less experienced woodworkers to achieve professional results.

👉 DOWNLOAD NOW!

Applications for Fixtures and Guides

The use of fixtures and guides spans a wide array of woodworking projects. Whether you’re constructing a large piece of furniture, creating custom cabinetry, or crafting detailed decorative items, these tools are essential. For instance:

- Cabinet Making: Using jigs and guides for precise cutting and drilling ensures that all parts fit together seamlessly.

- Decorative Work: Intricate cuts and designs require the stability and accuracy that only fixtures can provide.

- Mass Production: When creating multiple pieces of the same item, fixtures and guides ensure that each one is uniform, maintaining quality and saving time.

Function of Fixtures

Fixtures are the unsung heroes of the woodworking world. Ever wondered how craftsmen achieve those perfectly consistent cuts? Well, fixtures are your answer. They hold your workpiece securely in place, ensuring accuracy and repeatability. Why risk a masterpiece with shaky hands or misaligned cuts?

The importance of guides

Guides act as your roadmap through complex projects. They ensure that every cut, carve, and trim is done precisely where it needs to be. Can you imagine driving in a new city without Google Maps? That’s woodworking without guides—possible, but why make it harder?

Applications for Fixtures and Guides

From creating dovetail joints to cutting perfect circles, fixtures and guides expand the range of projects you can tackle. Whether it’s a custom furniture piece or intricate decorative work, these tools are your gateway to professional-grade craftsmanship.

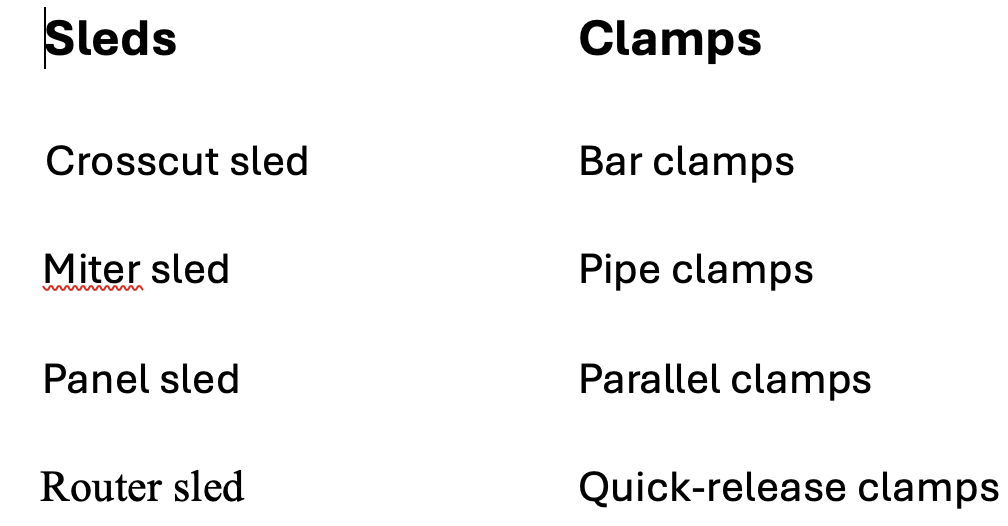

Sleds and Clamps

Precision is essential in woodworking, therefore sleds and clamps come in useful. These basic woodworking jigs give the stability and control necessary for cutting and shaping operations. By include sleds and clamps in your workshop, you can guarantee that your woodworking processes are accurate and efficient..

Benefits of Sleds

Sleds provide stability and precision, particularly for table saw operations. They glide along the saw’s fence, guiding your material straight through the blade. Ever tried to push a large piece of plywood through a saw without one? Not fun, right?

Power of Clamps

Clamps are the strong hands you wish you had. They hold pieces together while glue dries or secure your workpiece to a bench, preventing any movement during critical operations. Remember, in woodworking, movement is the enemy of precision.

Types of Sleds and Clamps

From bar clamps to frame sleds, each type serves a specific purpose. Choose based on the task at hand—for example, use a miter sled for perfect 45-degree cuts or a pipe clamp for large projects.

You may get a broad selection of sleds and clamps to match your specific woodworking needs; here are some examples.

Sleds and clamps are two of the most crucial jigs for woodworkers to have on hand for producing clean, accurate cuts. If you want to improve the quality of your woodworking projects, you can’t afford to overlook these vital tools.

Stops and Blocks

Accuracy is critical when working with wood, and woodworking equipment like stops and blocks are essential for achieving it. They enable you to make regular, perfect cuts without measuring each time.

To easily get consistent lengths, all you need is a stop, a simple but efficient jig that offers a stable position for your workpiece. Stops enable you to consistently and quickly replicate cuts without measuring each time, which increases efficiency and saves time.

Blocks, on the other hand, are multipurpose jigs that can be used for a variety of woodworking operations, such as setting a reference point, making a straight edge, or clamping your workpiece down. Blocks are particularly useful for cutting, shaping, and assembly, as they provide additional stability and control.

Tapered blocks are great for slanted cuts because to their stability and precision. Flip stops allow for rapid positioning changes, while adjustable stops make it simple to vary the length of your cuts.

Click here To Get Started

Benefits of Stopping and Blocking:

Stops and blocks make repetitive cuts a breeze. Need to cut multiple pieces to the same length? Set a stop on your miter saw, and you’re good to go. It’s like having a built-in measuring tape that guarantees accuracy every time.

Mark Rivers, a master carpenter, describes stops and blocks as “totally revolutionary” in terms of accuracy, efficiency, and flexibility.

It is very important to think of adding stops and blocks into your toolbox. this will allow you to focus on your woodworking journey with not fear when it come about taking accurate and precise measurements. This will make you achieve your work in an expert level results. Don’t worry they are friendly and very easy to use.

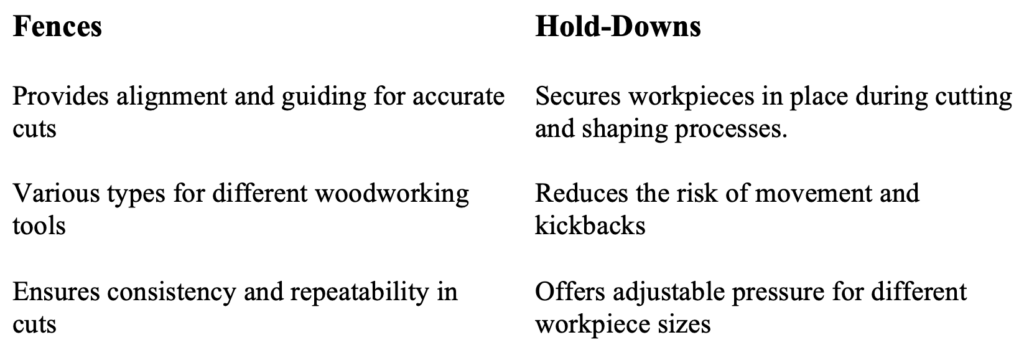

Fences and Hold-Downs

Fences

Fences are all about guidance and accuracy. They are particularly crucial on routers and table saws, where one wrong move could spell disaster. Think of them as the guardrails on your woodworking highway—they keep you straight and safe.

Hold-Downs

Hold-downs ensure your material doesn’t lift or shift during routing or cutting. They’re like having an extra set of hands—hands that never get tired or slip.

Featherboards

In the world of precision woodworking, maintaining control over your material during cuts can make the difference between a good finish and a great one. This is where featherboards come into play. Featherboards are among the most versatile and essential jigs in a woodworker’s arsenal, designed to enhance both the safety and quality of cuts by applying consistent pressure to the workpiece against a fence or tabletop.

The Role of Featherboards in Woodworking

Featherboards primarily function to keep the workpiece stable and secure against the tool’s fence or table surface, reducing kickback and ensuring a smooth, straight cut. Their design, featuring a series of angled fingers or “feathers,” allows them to flex and accommodate variations in wood thickness while maintaining constant, even pressure. This adaptability makes them particularly valuable when working with warped or bowed materials that can otherwise be challenging to manage.

Safety Enhancement

One of the critical benefits of using featherboards is the increased safety they provide. By firmly holding the workpiece during operations like routing, sawing, or dado cuts, featherboards help prevent the wood from wobbling or shifting, which can lead to dangerous kickbacks. Their use significantly reduces the risk of accidents, allowing the woodworker to focus on precision without worrying about unexpected movements.

Improving Cut Quality

Featherboards also play a significant role in improving the quality of your cuts. By ensuring that the workpiece is uniformly pressed against the fence or table, they eliminate the variations that can lead to jagged or uneven cuts. This is particularly important for fine joinery or any project where the finish and fit are paramount. The consistent tension applied by the featherboards results in smoother, more accurate cuts, enhancing the overall finish of your project.

Versatility in Applications

The utility of featherboards extends across various woodworking tools and applications. They are commonly used on tables saws, router tables, and band saws. Each setup might require a different type of featherboard, depending on the specific needs of the operation, such as the direction of the cut or the particular safety concerns involved.

Ease of Setup

Setting up a featherboard is relatively straightforward, which makes it an excellent tool for woodworkers of all skill levels. Most featherboards come with clamps or bolts that easily attach to standard miter slots or directly onto the tabletops of machines. This ease of installation allows for quick adjustments and removal, facilitating a seamless transition between different cuts and projects.

Miter Slot Featherboards

These are ideal for controlling the workpiece near the cut, applying consistent pressure, and maintaining safe operation. They fit snugly into the miter slots of your table saw or router table, providing that extra level of precision and safety.

Double Featherboards

Double the feathers, double the control. These are great for simultaneous pressure on the top and side of the material, especially useful in router table applications.

Flexible Featherboards

Flexible featherboards adjust to the shape of your workpiece, offering precise pressure without compromising the material. They’re perfect for irregularly shaped projects where traditional featherboards just won’t do.

Doweling Jigs and Mortising Jigs

The Advantages of Doweling and Mortising Jigs

Doweling and mortising jigs are pivotal for creating strong, seamless joints. Perfect for everything from building sturdy furniture to crafting intricate joinery, these jigs ensure your connections are tight and your projects are durable.

opting for-quality doweling and mortising jigs is an excellent decision for any woodworker trying to develop their abilities, as they give unlimited alternatives for producing attractive, strong, and intricately connected components that display your knowledge and attention to detail.

Circle-Cutting Jigs and Taper Jigs

Circle-Cutting Jigs

Perfect circles are not just satisfying to look at; they’re often essential in project design. A circle-cutting jig takes out the guesswork and gives you neat, precise circles every time.

Taper Jigs

Taper jigs are the go-to for adding elegance and style to any project, allowing for precise angle cuts. Want to add a sophisticated taper to a table leg? This is your tool.

Remember that it is very important to take safety measurement and keep your work space study. Think safety, remember to put on your safety equipment and follow procedures to prevent injuries or accident.

Feature Circle-Cutting Jigs Taper Jigs

How do you choose between the two? Consider the project—need precise circular cuts or elegant tapered legs? Your answer dictates the jig.

Jig Type Applications

Each jig serves unique purposes, opening up a world of possibilities. Whether shaping a piece of furniture or crafting a custom gift, the right jig can make your project stand out.

Conclusion

In woodworking, precision is the line between a project you’re proud of and one you wish you could forget. These top woodworking jigs not only enhance precision but also make the process more enjoyable and less stressful. Whether you’re a seasoned crafter or just starting out, incorporating these jigs into your workshop will lift your projects to new heights of craftsmanship.

Bonus Tip:

Always take the time to maintain your jigs. A well-cared-for jig will return the favour by performing perfectly for many projects to come.

Why not join Teds Woodworking to get his free famous and DIY Projects today to help you advance your trade. Joint today and get access to multiple different Plans from simple DIY Projects to complex furniture design pre made to help you save time in your journey. this is a great opportunity to help you improve.

Click Here T Get started

FAQ

- What’s the first jig I should buy?

Start with what your projects demand, but a good set of universal clamps and a basic sled can cover most bases. - Can jigs be self-made?

Absolutely! Many woodworkers craft their jigs, tailoring them to specific projects or needs. - Are there any safety concerns with jigs?

Yes, always ensure they are properly set up and secured before use. Safety first, always!

Remember, the right tools not only make your projects better, they make you a better woodworker. Happy crafting!

Sharing is caring!